L&E Battery, besser bekannt für die Marke Dinogy, ist derzeit einer der führenden FPV- und RC-Akkuhersteller. In diesem Artikel präsentieren wir dir ein spannendes Interview mit L&E/Dinogy über kommende Produkte, Lithium-Akkutechnologie und wir klären einige Mythen, die schon seit einiger Zeit rund um LiPo-Akkus existieren.

Fangen wir direkt mit unserem Dinogy Interview (deutsche Übersetzung) an.

Vielen Dank, dass Sie sich die Zeit für ein Interview auf Drone-Zone.de nehmen. Vielleicht könnten Sie kurz Ihre Position bei L&E Battery beschreiben, um unseren Lesern einen Überblick zu geben?

Mein Name ist Harrison Ho, ich arbeite seit 2009 mit Fokus auf den internationalen Vertrieb für L&E.

Für alle unsere Leser, die L&E Battery noch nicht kennen: Was macht L&E Battery und wie sieht die bisherige Geschichte des Unternehmens aus? Wie passen Dinogy-Akkus in die Unternehmensgeschichte?

Mit über 10 Jahren Erfahrung in der Entwicklung, Herstellung und Vermarktung von hochwertigen wiederaufladbaren Batterien ist L&E Battery Industrial Co. Ltd. ein bedeutender Anbieter mit einem guten Ruf und Sitz in China.

Heute liefern wir ein umfangreiches Spektrum an wiederaufladbaren Akkuprodukten an Elektrogerätehersteller, führende Batterieunternehmen und den Einzelhandel unter verschiedenen OEM- und internen Marken weltweit.

Bildquelle: L&E Battery | ©

Bildquelle: L&E Battery | ©Aufgrund der Schlüsseltechnologien und der Kernkompetenz auf dem Gebiet der wiederaufladbaren Batterien ist L&E überzeugt, dass unsere Produkte zum Erfolg unserer Kunden beitragen. Wir unternehmen stets alle erdenklichen Anstrengungen, um die Zuverlässigkeit unserer Produkte durch technologische Fortschritte und fortschrittliche Qualitätskontrolltests zu verbessern.

Wir sind bestrebt, neue Bedürfnisse der globalen Märkte genau zu identifizieren, damit wir fortschrittlichere und zuverlässigere Technologien und daraus resultierende Produkte entwickeln können, um diese Bedürfnisse zu erfüllen. Am Wichtigsten ist, dass wir ständig daran arbeiten, unseren Kunden seriöse und ehrlichen Produkte und Leistungen zu bieten.

Seit 2008 haben wir unsere Produktionslinien kontinuierlich erweitert, um ein möglichst umfangreiches Sortiment an wiederaufladbaren Batterien für Elektrogeräte, tragbare elektronische Geräte, medizinische und militärische Produkte, Notfallkits für die kommerzielle Beleuchtung sowie leistungsstarke Li-Po-Akkus für RC-Modelle und andere Hobby-Produkte anbieten zu können.

Nach mehrjähriger Forschungs- und Entwicklungsarbeit haben sich unsere leistungsstarken Li-Po-Akkus als großer Erfolg in der Praxis erwiesen. Durch die hohe Leistungsfähigkeit und die überlegene, langlebige Qualität unserer Produkte wurden zahlreiche Meisterschaften gewonnen und Geschwindigkeitsrekorde erzielt.

Zum Beispiel wurden die meisten NAMBA-Titel (größter Modellbootverband) mit Hilfe unserer Batterien errungen. Guinness World Records verzeichnete das schnellste RC-Auto, das mit 202 km/h unterwegs war – angetrieben von unserem Li-Po. Wir haben auch viele Auszeichnungen für professionelles FPV Racing, 3DX, F3P, F3A und so weiter ermöglicht.

In Bezug auf Dinogy hielt es mein Chef Henry 2010 für an der Zeit, dass wir unseren eigenen Premium-Markennamen kreieren, der sich über die ganze Welt verbreitet. Er bat mich, ein bestimmtes Tier in das zukünftige Markendesign aufzunehmen, das für „Kraft“ steht. Ich entschied mich schließlich für Dinosaurier + Energie = Dinogy.

L&E ist seit einigen Jahren ein etablierter Anbieter im Markt für Drohnenakkus. Können Sie uns einen kurzen Überblick über Ihr aktuelles Produktportfolio geben?

L&E hat eine breite Palette von Akkumodellen für die meisten RC-Modelle, einschließlich Softpacks für Drohnen, Flugzeuge, Airsoft-Guns, Boote und sogar Hardcase Packs für Autos, Trucks, etc.

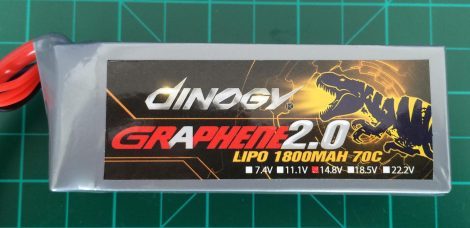

Alle unsere Li-Pos sind in drei Kategorien eingeteilt: Die preiswerte Einstiegsserie NANO-TECH, die mittlere GRAPHENE-Serie und die Premium-Serie GRAPHENE 2.0. Für jede dieser Kategorien sind Unterstufen mit unterschiedlichen Leistungs- und Kapazitätsspezifikationen vorhanden, die unseren Kunden eine breitere Palette von Auswahlmöglichkeiten bieten.

Natürlich sollten unfaire Gesetze, die darauf abzielen, ein unzweckmäßiges Maß an Beschränkungen für Drohnenbetreiber zu erwirken, um jeden Preis vermieden werden.

Harrison Ho, L&E Battery International Sales

Mit Blick in die Zukunft: Die meisten der von Ihnen angebotenen Marken scheinen sich auf den RC-Hobby-Markt zu konzentrieren. Wird sich L&E bei steigender Nachfrage nach Drohnen im Industriesektor auch auf Akkus für industrielle Drohnenanwendungen konzentrieren?

Tatsächlich produzieren wir seit vielen Jahren Akkus für Profi-Drohnen, die von unabhängigen Unternehmen professionell getestet und von UAV-Profis in der Praxis erprobt wurden. Zum Beispiel verwendete Heliguy unsere Industrial-Akkus am Set des berühmten Dokumentarfilms Planet Erde II.

Wir bieten 11000mAh, 16000mAh und 22000mAh Hochleistungs-Packs für Industriedrohnen und UAVs an. Kunden, die unsere Zellen getestet und verwendet haben, sind überzeugt, dass unsere Akkus eine höhere Spannung unter Last bieten als leichtere Zellen anderer Hersteller, da unsere Zellen mit mehr Elektrodenplatten als viele andere Konkurrenzprodukte ausgelegt sind. Mehr Elektrodenplatten bedeuten mehr Gewicht, aber auch, dass die Zellen/Packs effektiver/sicherer eine höhere Entladungsrate erreichen können, was für Industriedrohnen, insbesondere solche mit teurer Ausrüstung, sehr wichtig ist.

Zellen mit höherer Entladerate können höheren Strombelastungen durch den Start und plötzliche schnelle Bewegungen standhalten. Die daraus resultierende höhere Lastspannung liefert den Motoren effektiv mehr Drehzahl. Daher stellen Kunden fest, dass Drohnen mit unseren Li-Pos sich „leichter“ in der Luft anfühlen.

Als Akkuhersteller sind Sie in gewisser Weise von der Entwicklung des Drohnenmarktes abhängig. In vielen Ländern gibt es derzeit Bemühungen, den Einsatz von Drohnen strenger zu regulieren. Auf welche Dinge sollte der Gesetzgeber achten? Was sollte um jeden Preis vermieden werden?

Wie Sie wissen, bietet L&E Lösungen für andere Märkte an, die hochwertige wiederaufladbare Batterien benötigen. Wir sind nicht nur vom Drohnenmarkt abhängig – wir bieten Lösungen für alle anderen Arten von RC-Modellen, drahtlosen elektronischen Geräten und Produkten, die in verschiedenen anderen Märkten vertrieben werden.

Wir sind uns alle darüber im Klaren, dass es in vielen Ländern immer mehr Einschränkungen für Drohnen gibt, da vor allem leichtsinnige Freizeitpiloten Drohnen überall ohne Rücksicht auf Sicherheit fliegen. Es handelt sich hierbei um eine noch junge, wachsende Branche, und es ist verständlich, dass Gesetze verabschiedet und im Laufe der Zeit weiterentwickelt werden.

Der Gesetzgeber sollte den Freizeitpiloten besondere Aufmerksamkeit schenken, da hier oft Innovationen beginnen. Natürlich sollten unfaire Gesetze, die darauf abzielen, ein unzweckmäßiges Maß an Beschränkungen für Drohnenbetreiber zu erwirken, um jeden Preis vermieden werden.Dies führt nämlich nur zu einer raffinierten Umgehung der Regeln und am Ende zu Gesetzlosigkeit, die letztlich das Gegenteil von dem bewirkt, was die Gesetzgeber wollen.

FPV Racing (oder Drohnenrennen) wird als Sportart immer beliebter. Wie wichtig ist Ihrer Meinung nach der „FPV-Anteil“ des Drohnenmarktes für die zukünftige Entwicklung der Akkutechnologie?

Der boomende FPV-Rennsport förderte die Entwicklung leistungsstarker Akkus. Sie werden feststellen, dass immer mehr Akkus mit hohem C-Rating von verschiedenen Anbietern auf den Markt gebracht werden. Wir werden weiterhin innovativ sein, um die Anforderungen der wachsenden professionellen Rennsportindustrie zu erfüllen. Es handelt sich offensichtlich um einen wichtigen Sektor des gesamten Drohnenmarktes. Um auf dem Podium zu stehen, brauchen ernsthafte Piloten Hochleistungs-Packs.

Allerdings kümmern sich viele Li-Po-Hersteller aus Kostengründen nur oberflächliche um die Leistung und nehmen Lebensdauer und Sicherheit nicht ernst. Es ist daher wichtig, Folgendes zu verstehen: Unsere Wettbewerber wollen teils, dass die Packs der Kunden schnell verschleißen und häufig ausgetauscht werden, um mehr Umsatz zu erzielen, während wir auf der anderen Seite der Meinung sind, dass es wichtiger ist, Packs mit hoher Leistung, ausgezeichneter Sicherheit und ausgezeichneter Haltbarkeit trotz der damit verbundenen Kosten herzustellen.

Jeder Racer sollte höchste Zufriedenheit und Gewissheit durch seine Akkus erfahren, ohne Geld zu verschwenden und mehr Abfall für die Umwelt zu produzieren. Das war schon immer unsere Philosophie: Qualität und Sicherheit stehen an erster Stelle. Wir hoffen, dass das Bewusstsein dafür in Verbindung mit den Bedürfnissen des FPV-Sektors eine Wettbewerbslandschaft schafft, die letztlich zu einer sichereren Zukunft für den gesamten Markt führt.

Vor einiger Zeit hat die International Air Transport Association ihre Bedingungen für den Versand von Akkus geändert. Könnten Sie unseren Lesern erklären, was das für das Drohnenakku-Geschäft bedeutet und wie Sie eine Lösung gefunden haben?

Die neuen Luftfrachtbestimmungen für Li-Ionen-Batterien haben uns 2016, als sie angekündigt wurden, einige Probleme bereitet. Die Spediteure haben jedoch bald darauf eine Lösung gefunden, so dass die Belieferung jetzt kein Problem mehr ist.

Zumindest scheint die öffentliche Meinung zur Akkutechnologie zu sein, dass es in den letzten Jahren keine allzu großen Verbesserungen gegeben hat. Dennoch haben besonders leistungsstarke LiPo-Akkus für Drohnen- und RC-Anwendungen in den letzten Jahren einige Leistungssteigerungen erfahren. Könnten Sie uns einen kurzen Überblick über die letzten Meilensteine der Lithium-Polymer-Akkutechnologie geben?

Seit Sony Anfang der 90er Jahre die Massenproduktion der 18650er Zelle des Lithium-Ionen-Akkus erreicht hat, verbesserte sich die Technologie Jahr für Jahr. Die Energiedichte (Kapazität) wurde immer weiter gesteigert, jedoch waren Li-Pos immer noch nicht für R/C-Modelle geeignet, da diese eine zu hohe Leistungsabgabe erforderten.

Bildquelle: L & E | ©

Bildquelle: L & E | ©Im Zuge der Entwicklungen hatte die Hochkapazitätszelle für den Verbrauchermarkt bis Anfang 2000 eine wesentlich größere Nachfrage als der R/C-Bereich. Kokam brachte dann ein 20C- und 30C-Lithium-Polymer-Softpack mit hoher Entladerate auf den Markt, das sich als perfekt für RC-Modelle erwies, insbesondere für Flugzeuge, die leichte Packs benötigten.

Dann entdeckten einige Akkuhersteller in China, die gut darin waren NiMh- und NiCd-Akkus herzustellen, den potenziellen Markt und versuchten, auf Basis dieser neuen Technologie Li-Pos mit hoher Entladerate zu realisieren. Natürlich lief anfänglich nicht alles reibungslos. Es gab einen hohen Prozentsatz an Qualitätsproblemen wie vorzeitiges Puffing, tote Zellen und Low Voltage Probleme. Einige Jahre später traten einige der Manager und Ingenieure aus ihren ehemaligen Fabriken aus und gründeten ihr eigenes Unternehmen.

Unser Chefingenieur ist einer der ersten Pioniere in der Li-Po-Produktion. Er hat alle damaligen Schwierigkeiten gemeistert, die zu Misserfolgen geführt haben, und leitet heute die Mitarbeiter an, Li-Pos mit verbesserter Technologie und modernsten Produktionsanlagen herzustellen.

Heutzutage sind verschiedene Li-Po-Produktionen einander sehr ähnlich, sodass man keinen großen Unterschied feststellen wird. Im Wettbewerb stehen die Hersteller um höhere Leistung, bessere Qualitätskontrolle, mehr Sicherheit, niedrigere Preis und besseren Kundenservice. L&E zeichnet sich durch diese Schlüsselmerkmale aus. Wir verfügen über eine lange Historie, die dies unter Beweis stellt.

Eine Frage, die uns unsere Leser oft stellen, ist die Wahl zwischen Graphen- und Non-Graphen-Akkus. Wo ist der Unterschied? Und was sollte der Leistungsenthusiast wählen?

Nicht jeder Li-Po, der mit GRAPHENE gekennzeichnet ist, ist gut – viele Produzenten überbetonen das Wort „Graphen“ gerne. Ich möchte hier klarstellen, dass Graphene für nur einen kleinen Teil der meisten Zellchemie-Formeln verantwortlich ist. Es kann dazu beitragen, die Li-Po-Leistung und Lebensdauer bis zu einem gewissen Grad zu erhöhen, allerdings nicht in extremen Maßen.

Sie werden keinen Leistungsunterschied von 200% zwischen GRAPHENE- und NON-GRAPHENE-Packs feststellen. Daher sollten die Kunden Produkte nach ihren eigenen Anforderungen auswählen. Zum Beispiel, wenn Sie Anfänger und in der Lernphase sind, sind Fehler/Schäden unvermeidlich und Sie sollten kostengünstigere Packs verwenden. Wenn Sie ein erfahrener Racer sind und Ihr einziges Ziel darin besteht, Ihre Konkurrenten auf der Rennstrecke, auf der jedes Gramm und jeder Technologievorsprung zählt, zu besiegen, dann sollten Sie die erstklassigen Premium-GRAPHENE-Akkus verwenden. Es besteht somit Bedarf und Platz für sowohl graphen- als auch non-graphenbasierte LiPo-Packs.

Jeder Racer sollte höchste Zufriedenheit und eine gewisse Gelassenheit durch seine Akkus erfahren, ohne dabei Geld zu verschwenden und mehr Abfall für die Umwelt zu produzieren.

Harrison Ho, L&E Battery International Sales

Seit vielen Jahren werden LiPo-Akkus mit einem eher skeptischen Blick betrachtet. Viele Horrorgeschichten über das Abbrennen von Häusern durch LiPos wurden im Internet verbreitet. Wie weit sind wir mit diesen Sicherheitsaspekten bei modernen Lithium-Batterien heute?

Zuerst müssen Sie verstehen, warum Lithium-Batterien Feuer fangen können. Im Allgemeinen kann man es auf das sogenannte thermische Durchgehen (thermal runaway) zurückführen. Konkret sind die folgenden Faktoren dafür verantwortlich:

1. Mechanischer Missbrauch

Äußere Kräfte durch Stöße, Stürze, Einstiche oder Quetschdruck können die Zelle verformen und die Elektrodenplatten im Inneren verschieben. Sobald der Separator zerreißt, kann es zu einem internen Kurzschluss kommen und ein Brand kann durch das Austreten des Elektrolyten entstehen, welches brennbar ist.

2. Elektrischer Missbrauch

- a. Übermäßige Entladung (unter 3,0V/Zelle), die dazu führen kann, dass einige Chemikalien zwischen dem Separator aufgebläht werden und ihn durchdringen können, was die Wahrscheinlichkeit eines internen Kurzschlusses und nachfolgender Prozesse, ähnlich den oben genannten, erhöht.

- b. Überladung (über 4,20V/Zelle), die übermäßige hohe Ladespannung beschleunigt die Auflösung des Elektrolyts und erzeugt eine große Menge Gas, sodass sich immer mehr Lithiumkristalle auf der Oberfläche der negativen Elektrodenplatte bilden, was schließlich zu einem internen Kurzschluss und Feuer führt.

- c. Ein Kurzschluss durch zu hohen Strombedarf erzeugt eine große Menge an Wärme und verbrennt die Chemikalien.

- d. Überlastung: Ähnlich wie oben – Die unsachgemäße Verwendung des Akkus für andere Geräte, die einen höheren Strom als die vorgesehene Entladefähigkeit benötigen und somit eine Überhitzung verursachen können.

3. Herstellungsfehler, schlechtes Design und Qualitätskontrolle

Gesunde, funktionsfähige Zellen sollten mit genügend Platz im Inneren für die Elektroden und den Separator ausgelegt sein, da sonst bereits ein interner Kurzschluss entstehen kann, wenn sich die Zelle während des Ladevorgangs geringfügig ausdehnt.

Die Elektrodenplatten von Qualitäts-Li-Pos sollten eben und gleichmäßig hergestellt werden. Raue Oberflächen mit Partikeln können die Wahrscheinlichkeit einer Penetration erhöhen, wenn die Zelle Belastungen durch äußere Kräfte ausgesetzt ist.

Tatsächlich hat sich die Sicherheit von Lithium-Batterien mit den neuesten Technologien deutlich erhöht. Eine der großen Errungenschaften ist der 2012 veröffentlichte Ceramic Composite Separator. Im Vergleich zu herkömmlichen PP-Kunststoff-Separatoren hat er die folgenden Vorteile:

- Besserer mechanische Eigenschaften, sodass er nicht leicht eingerissen oder durchbohrt werden kann.

- Gute chemische Eigenschaften, korrosionsbeständig gegen organische Lösungsmittel wie Elektrolyt.

- Ausgezeichnete Temperaturstabilität, geringere Wärmeschrumpfung, höhere Temperaturbeständigkeit.

Hersteller von Lithium-Batterien könnten das Brandrisiko verringern, indem sie keramische Verbundseparatoren für die Produktion verwenden. Viele Hersteller ignorieren diese Technologie aus Kostengründen aber immer noch. Wir vernachlässigen Sicherheit und Qualität hingegen nicht und sind stolz darauf, neue Entwicklungen so schnell wie möglich zu in unsere Produkte einfließen zu lassen.

Obwohl sich die Lithium-Batterie-Technologie mit über 20 Jahren an Verbesserungen und Fortschritten stark weiterentwickelt hat, können unter bestimmten Umständen immer noch Feuer entstehen, da auch wir die grundlegende Natur des extrem reaktiven Lithiums nicht ändern können. Bei L&E arbeiten wir jedoch unermüdlich daran, diese Risiken zu minimieren, sowohl durch moderne Herstellungsverfahren als auch durch Schulung im Umgang mit der Sicherheit.

Ein sehr interessantes Thema, wenn es um Drohnenbatterien geht, ist der Mythos „Akkus müssen erst einmal eingewöhnt werden“, bevor man Höchstleistungen von einem Akkupack erwarten kann. Ist das wirklich wahr? Brauchen moderne LiPos einen Eingewöhnungszyklus, bevor sie genutzt werden sollten? Wenn, ja, wie sieht dieses Verfahren aus, wenn man über Best Practices spricht?

Hochleistungs-Li-Pos benötigen einen Break-In-Prozess um die volle Leistung zu erbringen, da Chemikalien während der Langzeitlagerung (ab 3 Monaten) träge werden. Der übliche Weg, die Zellen aufzuwecken, ist, sie mit 1C zu laden und mit 3C für 3 bis 5 Zyklen zu entladen.

Unterschiedliche Hersteller verwenden jedoch unterschiedliche Rezepturen von Chemikalien, was zu unterschiedlichen empfohlenen Verfahren führt.

Hitze ist der Feind jedes Li-Pos, unter anderem kann sie den Alterungsprozess von Chemikalien erhöhen.

Harrison Ho, L&E Battery International Sales

Zum Schluss und vielleicht am Wichtigsten: Lassen Sie uns ein wenig über die Qualität der Batteriezellen sprechen. Wie zeichnet sich ein gutes Hochleistungs-Lithium-Pack aus? Und was können die Verbraucher tun, um schlechte / minderwertige Akkus zu erkennen? Ist das C-Rating noch ein zuverlässiger Indikator?

Gute Hochleistungs-Li-Pos sollten einen niedrigen IR-Wert (Innenwiderstand) aufweisen, der einer der kritischsten Indikatoren ist. Je niedriger der IR-Wert, desto weniger Wärme erzeugt die Zelle und desto höher ist der Strom, den sie effektiv/sicher liefern kann.

Bildquelle: L & E | ©

Bildquelle: L & E | ©Hitze ist der Feind jedes Li-Pos, unter anderem kann sie den Alterungsprozess von Chemikalien erhöhen. Was die Qualität des gesamten Akkus betrifft, so gelten im Wesentlichen die oben genannten Konstruktionsstandards.

Schlechte Hochleistungs-Li-Pos haben die allgemeinen Merkmale einer Nieder- oder 0V-Spannungszelle, die möglicherweise auf einen kleinen internen Kurzschluss nach der Produktion zurückzuführen ist, welche dann anschließend nicht aus der Montage entfernt wurde. Dies ist natürlich auf schlechte Qualitätskontrollverfahren in Konkurrenzfabriken zurückzuführen.

Ein weiteres schlechtes Zeichen ist das vorzeitige Aufblähen, das auch bei normalem Gebrauch auftritt. Durch die schlechte Zellenabstimmung während der Produktion wird sich die Spannungdifferenz bei weiteren Lade-/Entladezyklen zwischen den einzelnen Zellen erheblich voneinander unterscheiden. Wir lassen nicht zu, dass diese B-Zellen es in unser Endprodukt schaffen.

Wenn eine der oben genannten negativen Eigenschaften vorhanden ist, werden die Chemikalien der Zelle beeinträchtigt und die Kapazität und Entladefähigkeit nehmen entsprechend ab. Das C-Rating ist kein genauer Indikator für die Qualität.

Besteht tatsächlich ein Unterschied zwischen billigen und hochwertigen LiPos?

Bei einigen bedauernswerten Herstellungsprozessen, die heute noch in Fabriken zum Einsatz kommen, gibt es sicherlich einen Unterschied zwischen kostengünstigeren LiPos und den teureren Premium-Packs. Um den Unterschied zu verstehen, müssen wir über Bedingungen und Techniken sprechen, die zu „Billig-LiPos“ während des herkömmlichen Herstellungsprozesses führen.

Dies sind einige der gebräuchlichsten Techniken zur Kosteneinsparung, die von skrupellosen Unternehmen eingesetzt werden:

1. Die Konfektionierung von Akkupacks mit B-Zellen ist leider in einigen Fabriken noch immer üblich. Eine Zelle wird als „B-Grade“ eingestuft, wenn die beabsichtigte Konstruktionsspezifikation aufgrund einer Vielzahl von Herstellungsproblemen nicht erzeugt oder erfüllt wird, entweder durch „natürlich“ (unvermeidlich) Ursachen oder durch fehlerhafte Ausführung. Das äußert sich dann in niedrigerer Spannung, höherer IR (Innenwiderstand) oder geringere Kapazität als erwartet.

Das Vorhandensein eines „mikro-internen“ Kurzschlusses würde natürlich auch unter diese Kategorie fallen. All diese Zustände werden als defekte Zelle betrachtet und es ist zu erwarten, dass jeder Hersteller unweigerlich einen kleinen Prozentsatz dieser defekten Zellen produzieren wird.

Allerdings nutzen einige Hersteller diese defekten Zellen bewusst in ihren endgültigen Akkupacks als Kosteneinsparungstaktik. Wir nehmen Sicherheit sehr ernst und glauben, dass die Verwendung dieser defekten Zellen die Sicherheit der Ausrüstung unserer Kunden und in einigen Fällen sogar ihren Leben gefährden könnte.

2. Konfektionierung von Akkupacks mit recycelten Zellen von Jump-Startern oder Power Banks. Jump-Starter-Zellen sind so konzipiert, dass sie nur eine kurzzeitig hohe Leistung liefern und daher keine kontinuierliche Hochstrombelastung aushalten.Wie erwartet, kommt es unter diesen Betriebsbedingungen zu Überhitzung und Puffing.

Power-Bank-Zellen sind, wie Sie vielleicht vermuten, speziell für die Entladung mit geringer Stromstärke konzipiert und sollten natürlich nicht in Hochleistungsanwendungen eingesetzt werden.

3. Vermischen eines hohen Anteils an kostengünstigen Materialien. Insbesondere wird eine höhere Menge an Nickel, Kobalt und Mangan (NCM) anstelle von reinen Lithium-Kobalt-Oxiden verwendet. Je mehr NCM in den Zellen vorhanden ist, desto geringer sind die Kosten, desto geringer ist die Lastspannung (niedrigere C-Rate) und desto kürzer ist der Lebenszyklus.

4. Erhöhung der Oberflächendichte chemischer Materialien an den einzelnen positiven und negativen Elektroden. Hier wird dann viel weniger Aluminium- und Kupferfolie für die gleiche Kapazitätsklasse verwendet, was den Innenwiderstand und die Temperatur erhöht. Dadurch wird auch die Entladungsspannung unter Last gesenkt.

5. Ersetzen von hochwertigen Aluminiumverbundsfolien (die nur in Japan hergestellt werden können) an den positiven und negativen Tabs und der Separatoren, durch billigere, im Inland (China) hergestellte Substitute.

6. Verkürzung oder vollständige Missachtung der wichtigen HTAP (Hochtemperatur-Alterungsprozess)-Qualitätssicherungsphase in der Produktion. Das bedeutet natürlich mehr Zeit/Tage gespart und mehr Produktionskapazität für die Fabrik. Ein Schritt bei dem L&E / Dinogy niemals Einschnitte vornehmen würde.

Mit diesen Informationen können wir nun schlüssig die Unterschiede zwischen billigen und hochwertigen LiPos ableiten.

1. Ein Premium-LiPo-Pack sollte über nahezu identische Spannungen, IR und Kapazitäten in allen Zellen verfügen. Billigere Packs haben stattdessen eine „schlechte Übereinstimmung“ in Bezug auf diese Werte.

2. Aufgrund hochwertiger Herstellungsverfahren der Zellen, der guten Zellenabstimmung in den Packs und gründlicher Qualitätskontrolltests haben hochwertige LiPos eine lange Lebensdauer, während billigere LiPos es mit toten 0-V-Zellen auf den Markt schaffen oder nach einigen regelmäßigen Einsätzen Puffing aufweisen.

3. Premium LiPos können problemlos über einen längeren Zeitraum gelagert werden. Billige LiPos haben Probleme, wenn sie mehrere Monate lang gelagert werden, ohne dass die Spannung durch Zwischenladung aufrecht erhalten wird.

Dies ist zum Teil auf Zellen zurückzuführen, die mikrointerne Kurzschlussprobleme haben und billige, im Inland (China) hergestellte Materialien verwenden, die zwar kurzfristig zu höheren Entladeraten führen können, aber letztendlich auch den Nebeneffekt einer schlechten Energiespeicherung aufweisen.

4. Premium LiPos haben eine hohe Entladefähigkeit, ohne die Langlebigkeit oder die Energiespeicherungseigenschaften zu beeinträchtigen. Billige LiPos neigen dazu, sich aufgrund höherer IR und unzulässiger beworbener Entladerate zu überhitzen, da sie mit B-Zellen ausgestattet sind.

5. Exzellente Sicherheit ist der grundlegende Standard für Premium-Packs. Dies ist ein oberstes Ziel von L&E / Dinogy. Billige LiPos setzen den Benutzer einem hohen Brandrisiko aus, da recycelte oder B-grade Zellen ungewollt und unbewusst durch den Nutzer missbraucht werden. Dieses Missverhältnis zwischen der beworbenen Entladerate und der tatsächlichen Qualität der Zellen im Pack führt zu einem größeren Auftreten von mikrointernen Kurzschlussproblemen. Darüber hinaus ist die im Inland (China) hergestellte, billigere Separatorschicht anfällig für Brüche, was ebenfalls einen solchen Mikrokurzschluss zur Folge haben kann.

Schockierenderweise gibt es viele „Fabriken“, die sich darauf spezialisiert haben, B-grade und recycelte Zellen von verschiedenen LiPo-Produzenten zu extrem niedrigen Kosten abzukaufen, um diese billigen Akkus anschließend mit einer schönen neuen Verpackung und einem neuen Etikett zu versehen und dann an Unwissende zu verkaufen.

Leider arbeiten viele Hersteller auf diese Weise und verwenden, wie oben erwähnt, billige, im Inland (China) hergestellte Materialien, um ihre Kosten zu senken und den Umsatz/Gewinn zu steigern. Mit diesen unehrlichen und unmoralischen Praktiken ist es offensichtlich, dass einige Hersteller sich nicht um die Unversehrtheit des Lebens oder der Ausrüstung ihrer Kunden kümmern. Ihr Hauptziel ist es, so viel Geld wie möglich zu verdienen.

Unser Versprechen ist es, in den von uns hart erarbeiteten Massenproduktionsprozessen niemals Kompromisse einzugehen oder an den notwendigen High-End-Materialien zu sparen. Wir können es uns nicht leisten, unseren Ruf zu schädigen oder unsere Kunden im Stich zu lassen.

Wettbewerber wechseln oft ihren Markennamen, wenn die Kunden aufgrund von Massenbeschwerden und Unfällen immer häufiger hinter die Tricks dieser Hersteller kommen. Aufgrund ihrer ungewöhnlich günstigen Preise haben sie kein Problem damit, das Geschäft unter einer neuen Marken wieder aufzubauen. Dies ist für den unerfahrenen Käufer attraktiv genug, um viele unschuldige Menschen leider in die Falle zu locken.

Wir glauben jedoch, dass immer mehr Kunden beginnen, diese unethischen Geschäftspraktiken zu erkennen. Immer mehr Profis und sogar Hobbybastler beginnen, die Vorteile von Premium-LiPos gegenüber den Gefahren und letztlich höheren Kosten zu schätzen, die dadurch entstehen, dass sie regelmäßig Geld für billigere Packs verschwenden müssen, da diese mit der Zeit schneller „sterben“. Viele unserer Kunden berichten regelmäßig, dass unsere Batterien auch nach mehreren Jahren noch viele Zyklen durchhalten.

Dieses Feedback über die Langlebigkeit und Qualität unserer Packs ist es, woran wir seit Beginn unserer Reise gearbeitet haben, um die Welt mit den besten wiederaufladbaren Batterien auf dem Markt zu versorgen. Längst haben wir interne Richtlinien festgelegt und eine Unternehmenskultur entwickelt, die sicherstellt, dass wir ehrlich, sicher und auf höchstem Niveau arbeiten, was zu einer besseren Zukunft der wiederaufladbaren LiPo-Technologie für alle führt. Wir sind bestrebt, diesen Standard noch Jahrzehnte lang aufrechtzuerhalten.

In diesem Zusammenhang: Welchen Wettbewerbsvorteil bringen L&E / Dinogy-Batterien im Vergleich zu anderen Akkumarken mit sich? Warum sollte jemand, der dieses Interview liest, sich für Dinogy Akkus entscheiden, wenn er/sie das nächste Mal aus dem Haus geht, um neue Packs zu kaufen?

Dinogy ist stolz darauf, den Standard für hochwertige Batterien zu setzen und es den Anwendern zu ermöglichen, Rennen zu gewinnen und Rekorde zu erzielen – und das alles unter Berücksichtigung der Sicherheit Ihrer wertvollen Ausrüstung. Wir sparen nicht bei der Qualität der Fertigungsmaterialien, nur damit wir die Billigsten auf dem Markt sein können, so wie einige der anderen Marken.

Darüber hinaus verfügen wir über ein strenges Qualitätssicherungsverfahren, um schlechte Zellen herauszufiltern (was die anderen Hersteller vernachlässigen), einschließlich überdurchschnittlicher HTAP-Teststandards (High Temperature Aging Process). Dieser Prozess ermöglicht es uns, einen hohen Prozentsatz (99%+) an schlechten Zellen herauszufiltern, bevor wir mit dem Rest unseres QA/QC-Prozesses fortfahren. Wir verwenden somit keine minderwertigen Zellen wie andere Hersteller.

Wir sind zwar sehr zufrieden mit unser nachgewiesene Erfolgsbilanz bei der Herstellung von wiederaufladbaren Hochleistungsakkus, besonders stolz sind wird jedoch darauf ein ehrlicher Hersteller zu sein, der Sicherheit, Langlebigkeit und Gesamtqualität seiner Akkus im Fokus hat. Wir sind uns der Risiken für alle Beteiligten bewusst.

Zum Abschluss unseres hochinteressanten Gesprächs – Was können wir von L&E und Dinogy im Jahr 2020 erwarten? Gibt es etwas, das Sie uns bereits verraten können?

Wir planen, unsere Website www.lnepower.com zu aktualisieren und hoffentlich im Jahr 2020 ein Lager in Europa einzurichten, um uns um eine bessere Versorgung in Europa zu kümmern. Darüber hinaus werden wir die Website www.dinogy.com und andere technische Initiativen starten, um die Markenbekanntheit und die Koordination unserer verschiedenen Niederlassungen auf der ganzen Welt zu erhöhen.

Die Forschung und Entwicklung von Batterien folgt immer den Marktanforderungen, wenn die Hersteller von RC-Modellen etwas Interessantes und von den Kunden gut akzeptiertes auf den Markt bringen, werden wir natürlich keine Mühe scheuen, unsere eigenen, verbesserten Akkuprodukte für die Kunden zu entwickeln. Darüber hinaus forschen, entwickeln und erfinden wir ständig intern und sind bereit für neue Trends.

Ihr könnt eine unübertroffenen, stärkere Internet- und Markenpräsenz weltweit erwarten! Wir fangen gerade erst an!

Vielen Dank, dass Sie sich die Zeit genommen haben für ein Interview auf Drone-Zone.de genommen haben.

Transparenzhinweis: Das Interview wurde textbasiert geführt. Die Fragen wurden dem Interviewpartner zur Verfügung gestellt, um auf diese in Schriftform zu antworten. Das Interview wurde aus dem Englischen übersetzt.